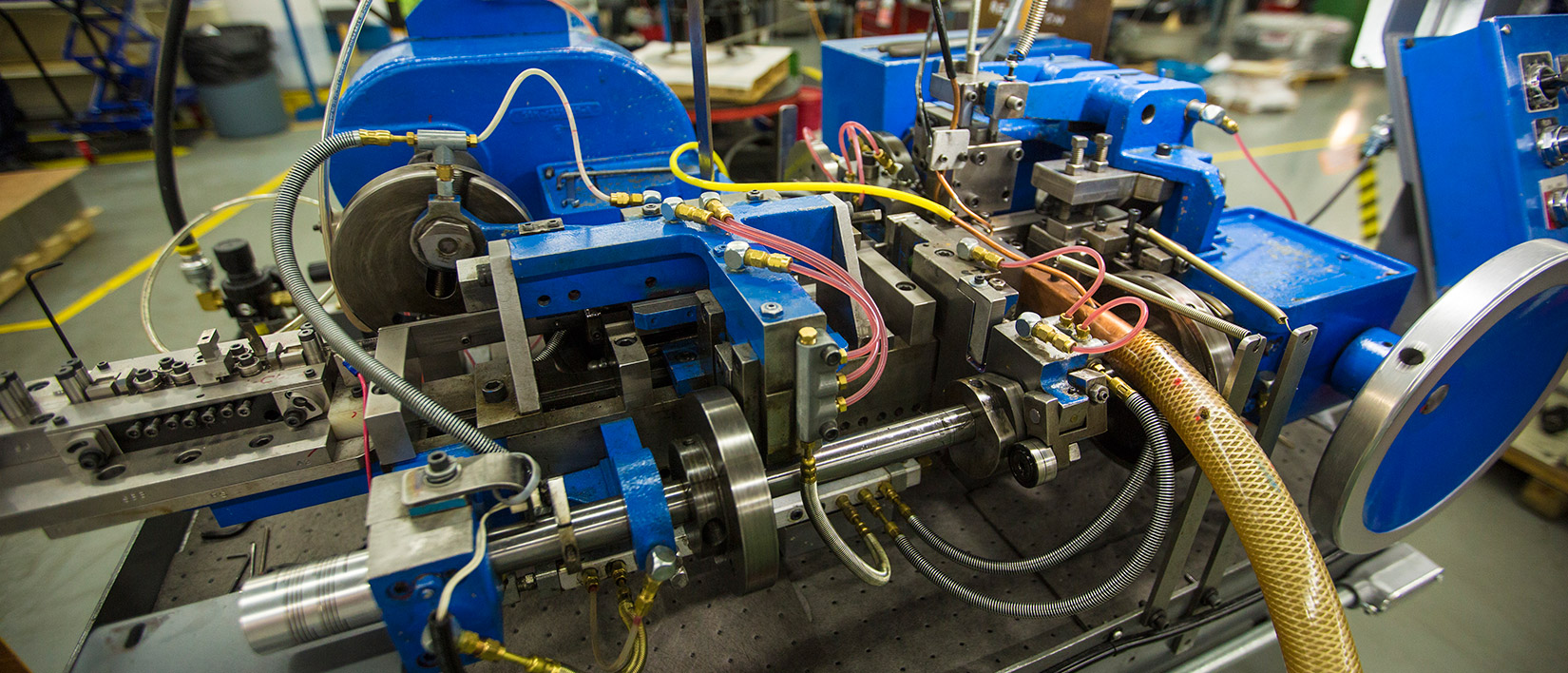

Fourslide Production

CSS offers a wide range of advanced slide forming technologies that deliver cost-effective solutions for intricate springs, stampings, and wire forms. Our state-of-the-art equipment—featuring servo-driven systems and integrated die protection—supports both high precision and repeatability. We continue to expand our capabilities to meet evolving customer needs. Multislide forming remains a highly economical option when the material type, part complexity, and production volume align. Our progressive slide forming equipment has consistently delivered excellent results across a variety of industries, including medical, aerospace, electronics, and more.

| Flat Stock Thickness |

Flat Stock Width |

Wire Diameter |

| .005" to .160" |

.080" to 3.500"

(depending on thickness) |

.010" to .240" |

Our fourslide, multislide, vertislide, and Bihler machines offer a cost-effective alternative to traditional power press tooling. Unlike progressive dies, slide forming eliminates the need for a carrying strip, allowing for more efficient material usage and reduced waste, resulting in lower part costs.

- Fourslide tools are a cost-effective option compared to traditional power press tools, offering accurate and repeatable part production.

- Bihler technology features advanced servo slide capabilities, allowing for both radial and linear forming using interchangeable cassette tooling.

- Multislide machines are similar to fourslide systems but can accommodate up to eight slides, providing additional forming motions and often handling slightly thicker parts.

- Vertislide machines are a variation of fourslide or multislide equipment, with slides and tooling configured in a vertical orientation.

Need a One-Page Summary of Our Capabilities?

Download our capabilities overview for a quick, shareable snapshot of what CSS can do, from engineering to production.

Looking for Cost-Effective Global Manufacturing?

Explore our Asian manufacturing capabilities, backed by ISO-certified partners and proven global supply chain integration.

Global Precision Manufacturing & Supply Chain Support

Countries We Supply

What Our Clients Say about Working with CSS

"I haven't worked directly with a whole lot of spring manufacturers in the past, but it's been absolutely great working with CSS so far. They are head and shoulders above other folks I've worked with – quick reply, detailed/thorough, helpful in teaching the process, forthright in offering solutions, etc. I really appreciate the help thus far and looking forward to continuing to work together."R&D Engineer, Top Tier Surgical Device Company"I have been impressed with the professionalism and execution of your company and personnel, and I'd like to extend a sincere thank you. I can honestly say it has been a pleasure working with you and I look forward to continuing business with your company!"R&D Engineer, BD"One of the most important things we look for in a partner is value engineering and value analysis to help us reduce costs. CSS provided us with virtually a one-stop-shop for very fast feedback that helped us design new models for manufacturability."VP of New Product Development, Smith & Wesson"Connecticut Spring & Stamping is an exceptional supplier. Their engineering teams have supported Teleflex Medical through successful product designs & launches. They respond quickly whenever the need arises, and deliver with a world class level of service and quality."Teleflex Medical"Your organization has shown an outstanding quality history on all of the various parts you ship to Colt; a true commitment to supplying our company with a quality product."Director of Quality, Colt Defense

View Full PDF

View Full PDF