Spring Production

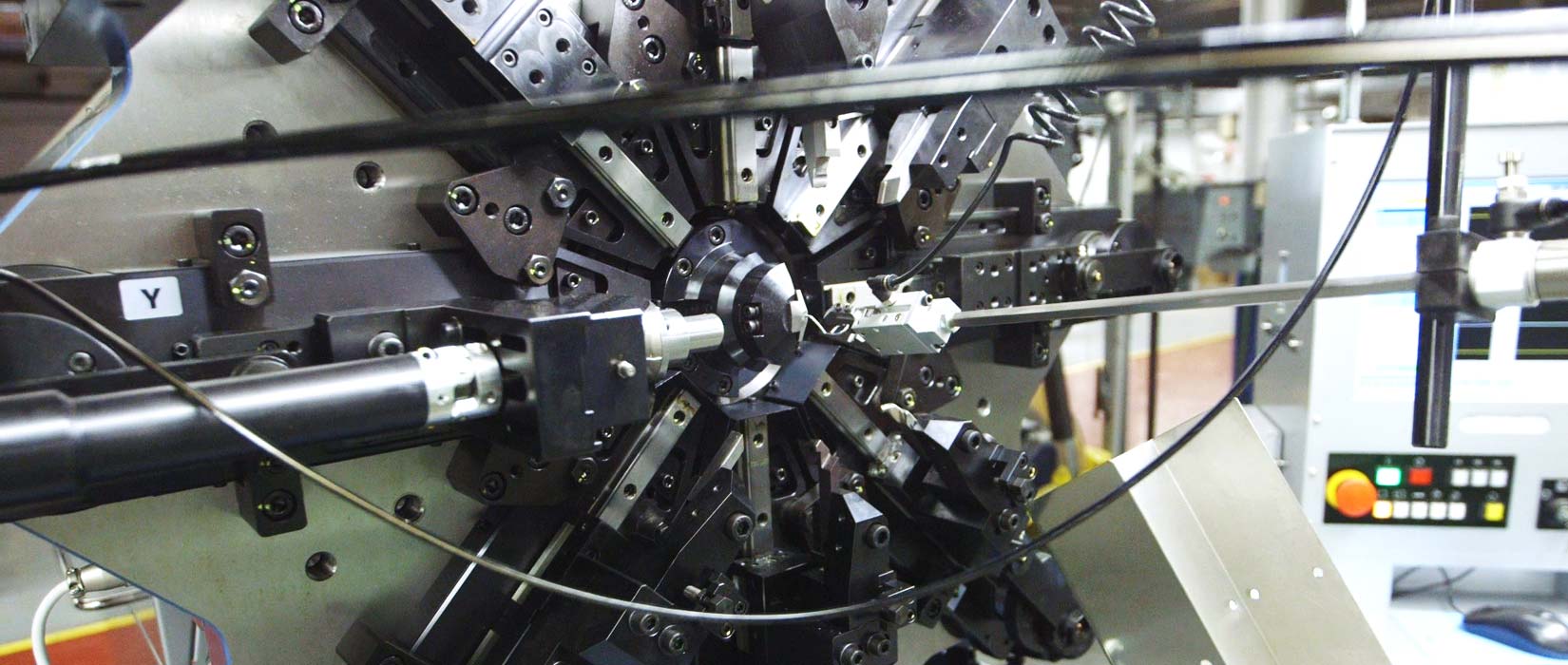

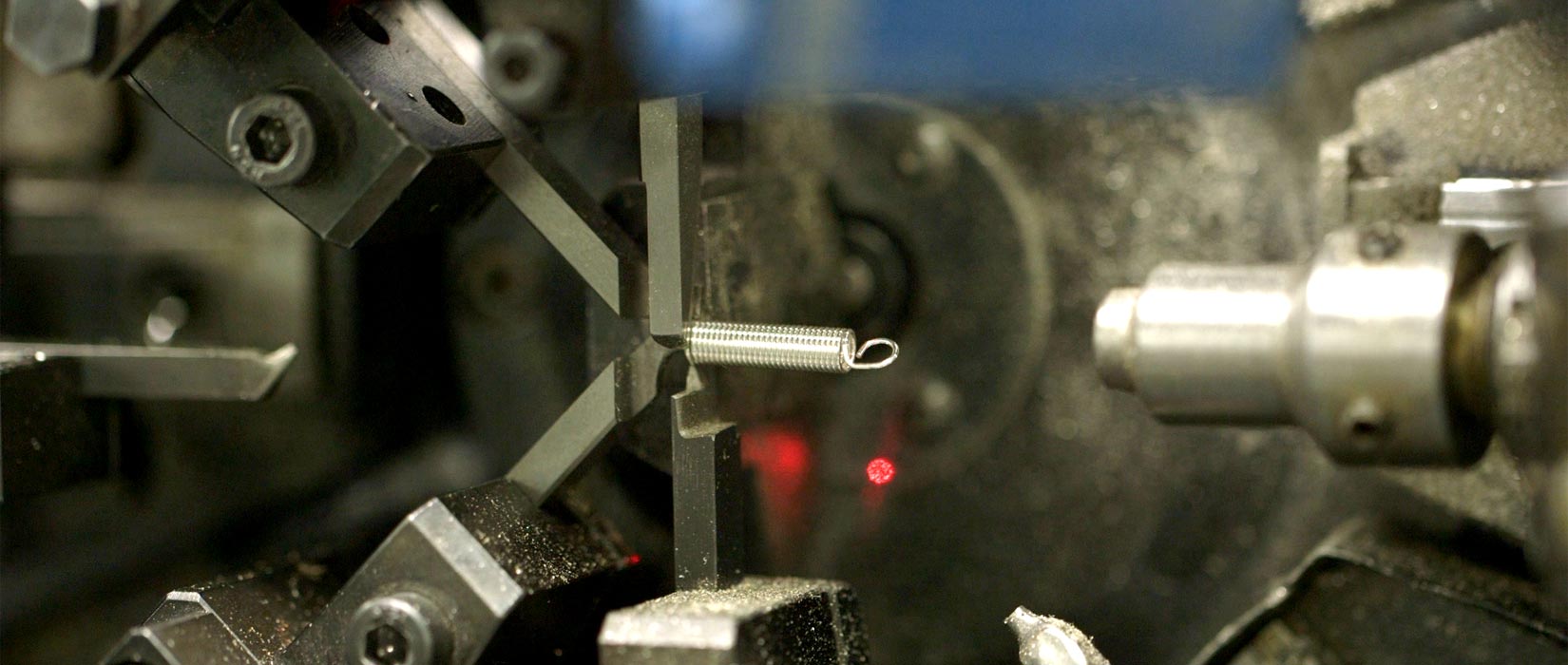

CSS specializes in engineering springs for manufacturability and consistent performance, helping our customer’s perfect designs while reducing costs. We produce springs to exact customer specifications using round, square, braided, and shaped wire, sourced from a wide variety of standard and specialty materials. Our capabilities include both short-run and high-volume production, supported by a broad range of coilers, automatic looping machines, grinding, and secondary processes to bring your spring designs to life.

| Wire Diameters |

| Small Coil |

.004" to .020" |

| Medium Coil |

.020" to .080" |

| Large Coil |

.080" to .350" |

Our engineers use prototyping to reduce costs and improve spring manufacturability for our customers. Typically, five to ten prototype springs are produced for early testing. Each spring is evaluated for load capacity, diameter, and material, with multiple iterations and adjustments made until it meets the customer’s exact requirements.

What sets CSS apart is our expert engineering support throughout the spring prototyping phase. This collaboration enables customers to explore various design options, often generating one or two refined variations that undergo further testing before finalizing the spring for commercial production.

Need a One-Page Summary of Our Capabilities?

Download our capabilities overview for a quick, shareable snapshot of what CSS can do, from engineering to production.

Looking for Cost-Effective Global Manufacturing?

Explore our Asian manufacturing capabilities, backed by ISO-certified partners and proven global supply chain integration.

Global Precision Manufacturing & Supply Chain Support

Countries We Supply

What Our Clients Say about Working with CSS

"I haven't worked directly with a whole lot of spring manufacturers in the past, but it's been absolutely great working with CSS so far. They are head and shoulders above other folks I've worked with – quick reply, detailed/thorough, helpful in teaching the process, forthright in offering solutions, etc. I really appreciate the help thus far and looking forward to continuing to work together."R&D Engineer, Top Tier Surgical Device Company"I have been impressed with the professionalism and execution of your company and personnel, and I'd like to extend a sincere thank you. I can honestly say it has been a pleasure working with you and I look forward to continuing business with your company!"R&D Engineer, BD"One of the most important things we look for in a partner is value engineering and value analysis to help us reduce costs. CSS provided us with virtually a one-stop-shop for very fast feedback that helped us design new models for manufacturability."VP of New Product Development, Smith & Wesson"Connecticut Spring & Stamping is an exceptional supplier. Their engineering teams have supported Teleflex Medical through successful product designs & launches. They respond quickly whenever the need arises, and deliver with a world class level of service and quality."Teleflex Medical"Your organization has shown an outstanding quality history on all of the various parts you ship to Colt; a true commitment to supplying our company with a quality product."Director of Quality, Colt Defense

View Full PDF

View Full PDF