Stamping Production

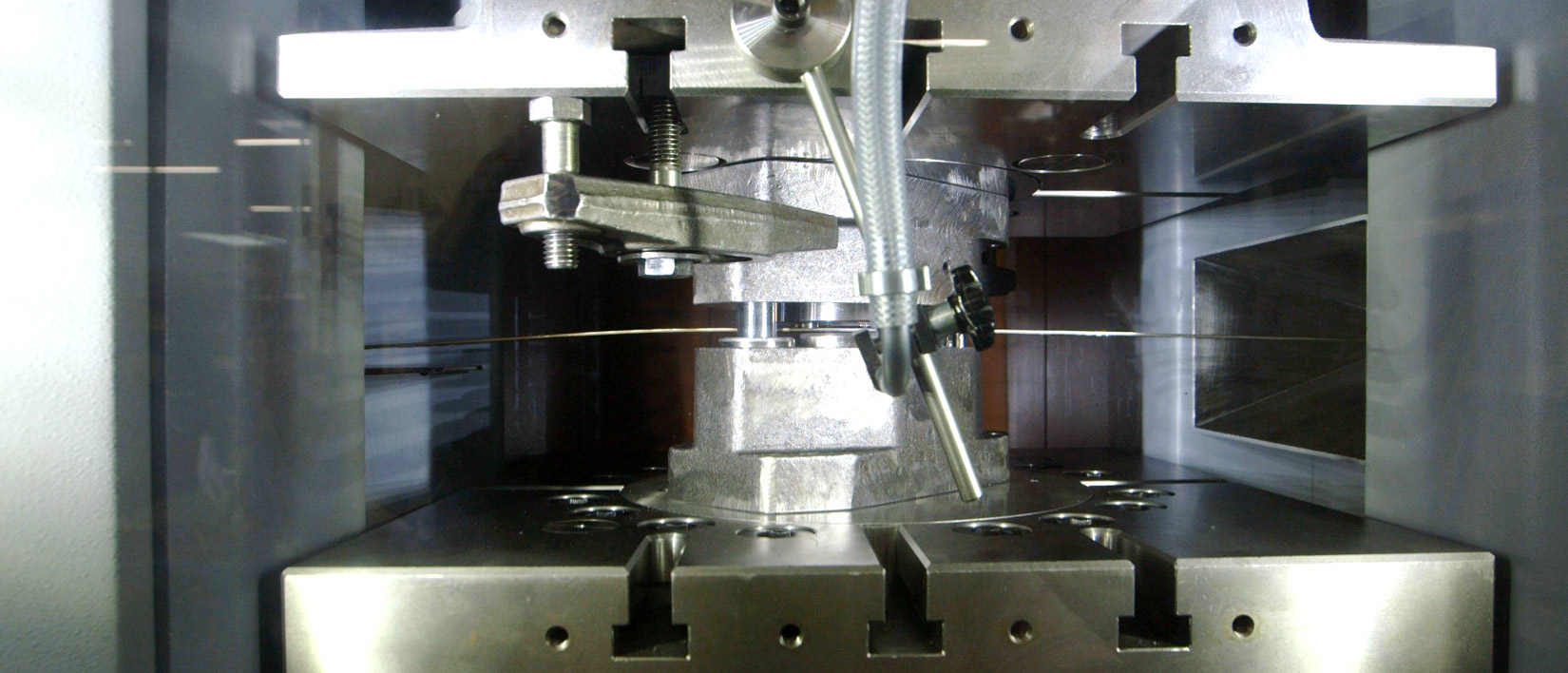

Progressive tooling is the cornerstone of CSS’s metal stamping division. We specialize not only in manufacturing tight-tolerance, complex stampings but also in designing and producing the precision tooling that those parts demand. Our state-of-the-art facilities are equipped with Seyi, Minster and Bruderer presses ranging from 30 to 330 tons, offering high-speed progressive die stamping, in-die tapping, modular die configurations, short-run capabilities, and fine blank stamping.

We produce stampings from a wide variety of raw materials, tailored precisely to customer specifications. Our metal stamping expertise is especially evident in the medical industry—where we have manufactured components such as drive channels, jaws, articulation parts, grasper arms, and titanium clips for assemblies used in handheld medical devices.

| Material Thickness |

Stock Width |

| .004" to .250" |

Up to 24" |

Many of our clients’ stampings require secondary operations such as machining, welding, heat treating, finishing treatments, additional stamping or forming, and assembly. Our extensive secondary operations department is equipped with presses ranging from 2 to 75 tons, enabling us to complete unique part features that cannot be incorporated into the primary progressive tooling.

Need a One-Page Summary of Our Capabilities?

Download our capabilities overview for a quick, shareable snapshot of what CSS can do, from engineering to production.

Looking for Cost-Effective Global Manufacturing?

Explore our Asian manufacturing capabilities, backed by ISO-certified partners and proven global supply chain integration.

Global Precision Manufacturing & Supply Chain Support

Countries We Supply

What Our Clients Say about Working with CSS

"I haven't worked directly with a whole lot of spring manufacturers in the past, but it's been absolutely great working with CSS so far. They are head and shoulders above other folks I've worked with – quick reply, detailed/thorough, helpful in teaching the process, forthright in offering solutions, etc. I really appreciate the help thus far and looking forward to continuing to work together."R&D Engineer, Top Tier Surgical Device Company"I have been impressed with the professionalism and execution of your company and personnel, and I'd like to extend a sincere thank you. I can honestly say it has been a pleasure working with you and I look forward to continuing business with your company!"R&D Engineer, BD"One of the most important things we look for in a partner is value engineering and value analysis to help us reduce costs. CSS provided us with virtually a one-stop-shop for very fast feedback that helped us design new models for manufacturability."VP of New Product Development, Smith & Wesson"Connecticut Spring & Stamping is an exceptional supplier. Their engineering teams have supported Teleflex Medical through successful product designs & launches. They respond quickly whenever the need arises, and deliver with a world class level of service and quality."Teleflex Medical"Your organization has shown an outstanding quality history on all of the various parts you ship to Colt; a true commitment to supplying our company with a quality product."Director of Quality, Colt Defense

View Full PDF

View Full PDF