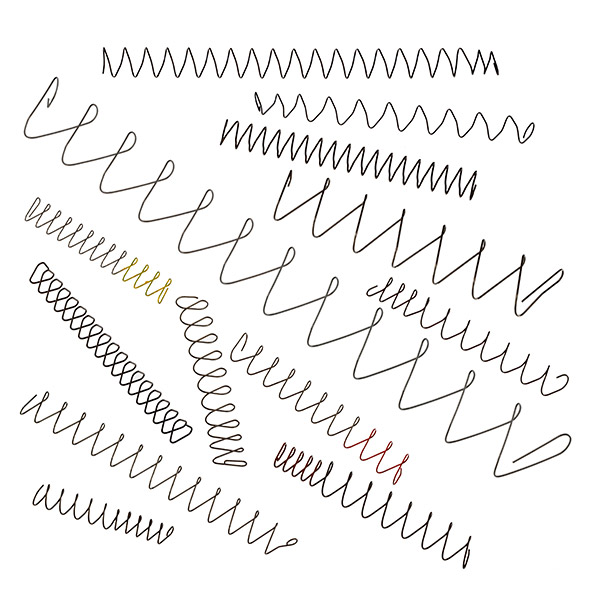

| Custom Springs Engineered for Precision, Performance & Durability

Explore our full range of compression, extension, torsion, double torsion, and magazine springs—manufactured to exact specs using high-performance materials for demanding applications

|

At CSS, we manufacture high-performance springs to precise customer specifications, supporting everything from prototyping to full-scale production.

Our capabilities span a wide range of wire diameters—from .004" to .350"—and materials including stainless steel, music wire, chrome silicon, and specialty alloys.

Whether your application requires energy storage, torque, compression, or tension, we engineer each spring to meet tight tolerances, exact force requirements, and challenging environmental conditions.

From medical devices and aerospace systems to defense platforms and consumer products, our springs are built to perform reliably where precision matters most.

Helical compression springs are designed to resist applied compression forces or store energy in the push mode. Typically made from round wire in a straight cylindrical shape, these springs can feature a variety of helical end types, including plain, ground, or squared ends.

Extension springs are designed to store energy and exert a pulling force. They are manufactured from round wire that is tightly coiled with an initial amount of tension built in. Unlike compression springs, extension springs typically do not have their sets removed, allowing them to maintain their preload for reliable performance in tension-based applications.

Torsion springs are helical coils that store mechanical energy when twisted, rather than compressed or extended. They exert a torque or rotary force when the ends of the spring are rotated relative to each other. Special care must be taken when handling or adjusting large torsion springs, as they can store significant amounts of energy and may pose safety risks if not properly managed.

Consist of one set of coils coiled right hand and one set of coils coiled left hand. These coils are connected, usually with an unwound section between the winds and work in parallel.

CSS manufactures an extensive variety of magazine springs for firearm and defense applications. Spring material sizes range from .033" to .062" and typical spring materials for these applications include Music Wire, Rocket Wire, 17-7 PH, and Chrome Silicon.